Using The Isothermal Transformation Diagram

On the isothermal transformation diagram for a 045 wt c fe c alloy sketch and label the time temperature paths to produce the following microstructures. Though usually used to represent transformation kinetics for steels.

What Is The Difference Between Cct And Ttt Curve By An Easy Example

What Is The Difference Between Cct And Ttt Curve By An Easy Example

2 rate of transformation.

Using the isothermal transformation diagram. F temperatures for martensite. Mse 300 materials laboratory procedures university of tennessee dept. It is also called isothermal transformation diagram definition.

An isothermal transformation diagram is only valid for one specific composition of material and only if the temperature is held constant during the transformation and strictly with rapid cooling to that temperature. We have plotted along the x axis the time and its in the scale of logarithms and. Davenport and bain were the first to develop the ttt diagram of eutectoid steel.

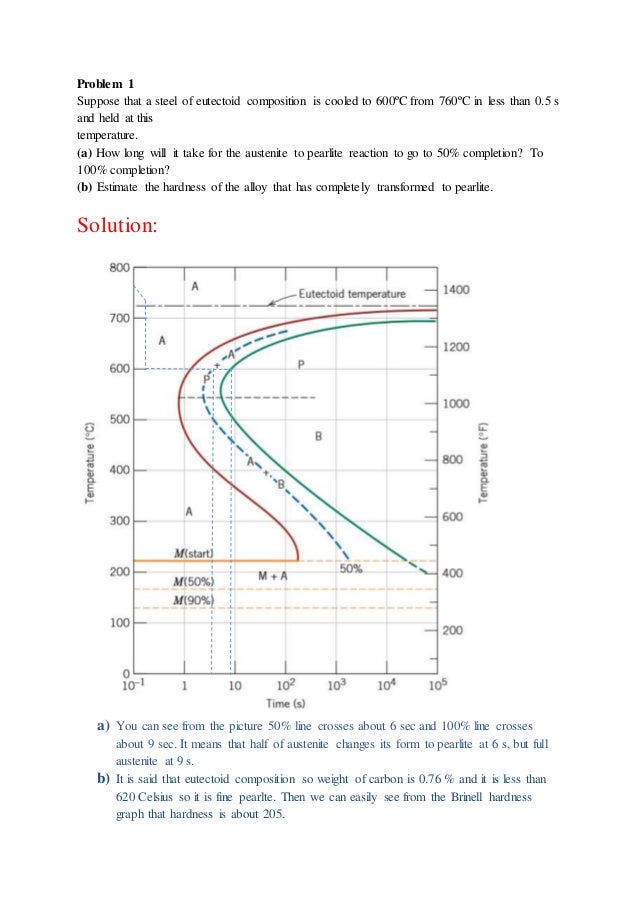

The higher the temperature the thicker the layers. Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition shown in the figure describe the final microstructure constituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments. These are the times asked for in the problem statement.

Ttt diagram stands for time temperature transformation diagram. The thickness of the ferrite and cementite layers in pearlite is 81. The eutectoid steel composition.

The complete isothermal transformation diagram for an iron carbon alloy of eutectoid composition. Phase diagram phase transformations ent 145 materials engineering chapter 10 phase transformations. The absolute layer thickness depends on the temperature of the transformation.

So here is our isothermal transformation diagram for. A from figure 1022 a horizontal line at 550 c intersects the 50 and reaction completion curves at about 25 and 6 seconds respectively. 100 79 ratings using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments.

Ttt diagrams give the kinetics of isothermal transformations. Were looking at the temperature on the y axis. Of materials science and engineering 20.

Solution we are called upon to consider the isothermal transformation of an iron carbon alloy of eutectoid composition. Ttt diagram gives 1 nature and type of transformation.

Solved Using The Isothermal Transformation Diagram For An

Solved Using The Isothermal Transformation Diagram For An

Transformation Diagrams Cct Ttt

Transformation Diagrams Cct Ttt

Expanding Time Temperature Transformation Ttt Diagrams To

Expanding Time Temperature Transformation Ttt Diagrams To

Isothermal Time Temperature Precipitation Diagram For An Aluminum

Isothermal Transformation Diagram Wikipedia

Isothermal Transformation Diagram Wikipedia

Transformation Diagrams Cct Ttt

Transformation Diagrams Cct Ttt

Peak Movement Of A C 2 0 0 And B A 2 0 0 With The Isothermal

Peak Movement Of A C 2 0 0 And B A 2 0 0 With The Isothermal

Solved Using The Isothermal Transformation Diagram For A 0 45 Wt C

Ttt Diagram Compu Ibmdatamanagement Co

Ttt Diagram Compu Ibmdatamanagement Co

Draw A Neat Ttt And Cct Diagram Of 0 8 Carbon Steel And Label All

Metals Free Full Text Method To Evaluate The Kinetics Of Bainite

Metals Free Full Text Method To Evaluate The Kinetics Of Bainite

Using Isothermal Transformation Diagram

Practical Maintenance Blog Archive I T Diagram And Cooling Curves

Quiz Ch 10 Solutions Pdf Using The Isothermal Transformation

Quiz Ch 10 Solutions Pdf Using The Isothermal Transformation

Draw A Neat Ttt And Cct Diagram Of 0 8 Carbon Steel And Label All

Steel Wiki Heat Treatment Interstahl Stahlhandel

Steel Wiki Heat Treatment Interstahl Stahlhandel

0 Response to "Using The Isothermal Transformation Diagram"

Post a Comment